Products Partgowal

Raw Ores and Processed Materials

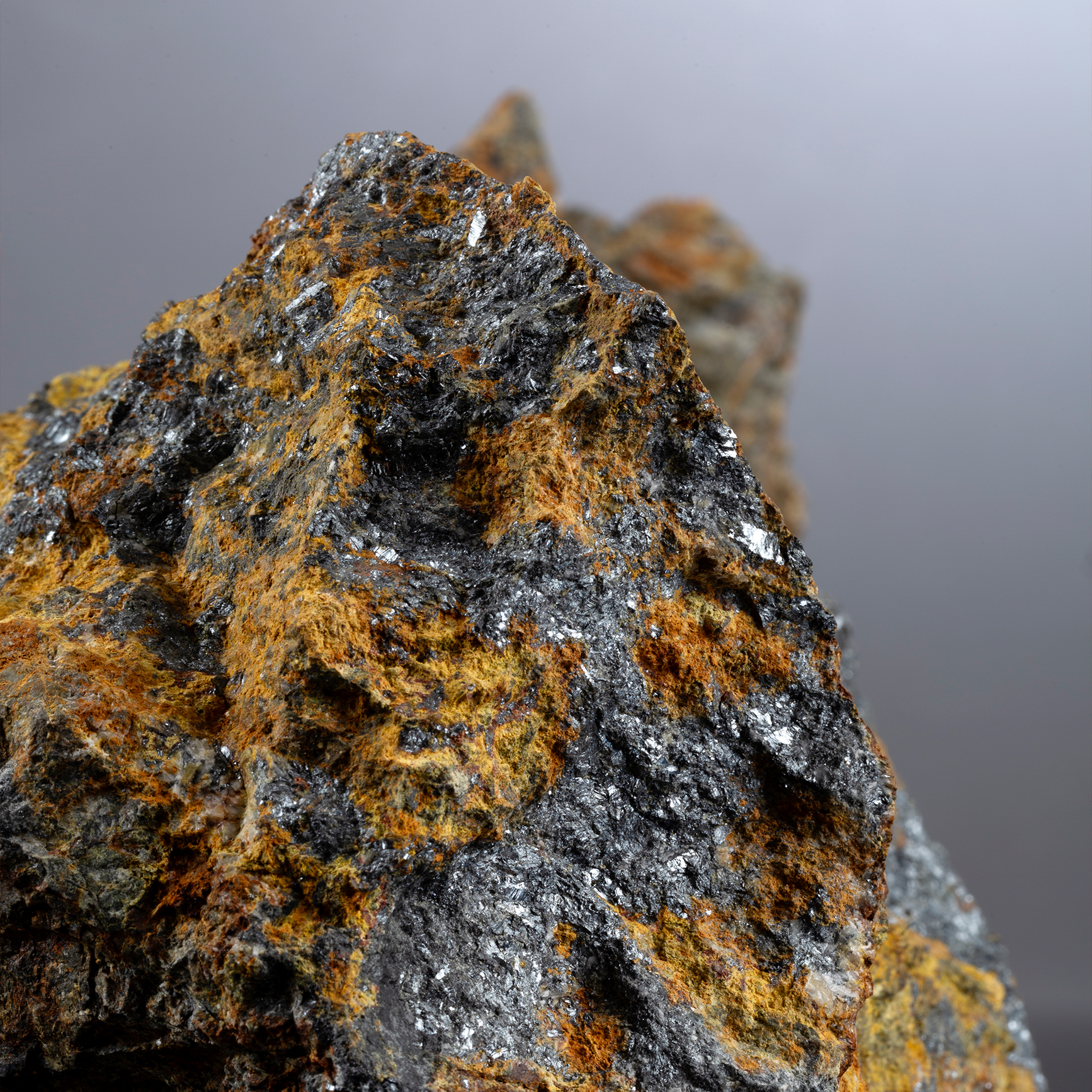

Chromite Ore

FeCr₂O₄

Chromite ore is the primary source of the metal chromium. It is a dark gray to black oxide mineral found in igneous and sedimentary rocks. Chromium is extracted from this ore and plays a vital role in the steel and alloy industries.

Characteristics of Chromite Ore:

• Relatively high hardness (5.5 to 6 on Mohs scale)

• High specific gravity (4.5 to 4.8 g/cm³)

• High thermal resistance

• Dark color with metallic to sub-metallic luster

• Chemical stability against oxidation

Applications of Chromite Ore:

• Production of ferrochrome (raw material for stainless and special steels)

• Manufacturing of heat- and corrosion-resistant alloys

• Production of refractory materials for furnace linings

• Preparation of industrial chemicals (e.g., chromium dioxide for pigments)

• Used in foundry industry as chromite sand

Copper Ore

CuO -Cu₂S-CuFeS₂

Copper ore is a mineral-rich rock that contains extractable quantities of copper metal. It is typically found in igneous, sedimentary, and metamorphic rocks and serves as the main source of copper supply for various industries.

Characteristics of Copper Ore:

• Distinct colors (green, blue, reddish-brown)

• High electrical and thermal conductivity

• Relatively high density

• Prone to oxidation when exposed to air

• High economic value due to metal content

Applications of Copper Ore:

• Extraction and production of pure copper for electrical and electronic industries

• Manufacturing of electrical wires and power transmission cables

• Production of alloys such as brass (copper & zinc) and bronze (copper & tin)

• Use in construction industry (pipes, fittings, roofing)

• Production of industrial parts, transportation equipment, and defense components

Antimony Ore

Sb₂S₃

Antimony ore contains the element antimony (Sb), typically found in the form of stibnite (Sb₂S₃). This material is used for producing antimony metal and its chemical compounds.

Characteristics of Antimony Ore:

• High specific gravity

• Corrosion resistance

• Medium hardness

• Brittle at low temperatures but excellent hardening agent in alloys

Applications of Antimony Ore:

• Production of wear-resistant alloys

• Additive in battery manufacturing (lead-acid batteries)

• Manufacturing of flame retardants

• Use in paint and ceramic industries

• Chemical industry for various additives

Fluorite Ore

CaF₂

Fluorite ore, also known as fluorspar, is a mineral composed of calcium fluoride (CaF₂) and serves as the primary source of fluorine for industrial applications. Due to its specific physical and chemical properties, it is used in metallurgy, chemical production, and ceramics.

Characteristics of Fluorite Ore:

• Moderate hardness (about 4 on Mohs scale)

• Good transparency and glassy luster

• Resistance to acids and high temperatures

• High melting point (around 1360°C)

Applications of Fluorite Ore:

• Used as a flux in steelmaking and foundry industries

• Production of hydrofluoric acid

• Manufacturing of ceramics and glazes

• Optical industry (lens and prism production)

• Chemical and pharmaceutical industries

Copper Concentrate

CuS -CuFeS₂-Cu₂S

Copper concentrate is the product of processed copper ore obtained through crushing, flotation, and impurity separation. It contains a high percentage of copper (Cu) and is used as the raw material for producing refined copper in smelting and refining industries.

Characteristics of Copper Concentrate:

• High copper content (approximately 20% to 30%)

• Contains sulfur (S)

• May include trace elements such as gold (Au), silver (Ag), molybdenum (Mo), and iron (Fe)

• Grayish-green to brownish color

Applications of Copper Concentrate:

• Production of refined copper through smelting and refining

• Electrical and electronics industries (wires, cables, electronic circuits)

• Construction industry (pipes, fittings, cladding)

• Automotive industry (electrical and motor parts)

• Production of copper alloys (brass, bronze)

Antimony Concentrate

Sb₂S₃

Antimony concentrate is obtained from mining and processing antimony-bearing ores. It contains a high percentage of antimony (Sb) and is used as a raw material for the production of antimony ingots and chemical compounds across various industries.

Characteristics of Antimony Concentrate:

• High antimony content

• Typically, gray to dark silvery color

• Relatively high density

• Corrosion resistance

• Easily meltable at lower temperatures than many other metals

Applications of Antimony Concentrate:

• Production of antimony ingots

• Battery manufacturing industry (improving the lifespan of lead-acid batteries)

• Manufacturing of corrosion-resistant alloys

• Chemical industry (production of antimony trioxide as a flame retardant)

• Electronics industry (used in semiconductors)

• Paint and plastic industries (as flame-retardant additives)

Chromite Concentrate

FeCr₂O₄

Chromite concentrate is a processed product derived from chromite ore (FeCr₂O₄). Through crushing and gravity or magnetic separation, the chromium content (Cr₂O₃) is upgraded, and impurities are reduced. It is produced as powder or granules and primarily used in metallurgy, especially for ferrochrome and stainless-steel production.

Characteristics of Chromite Concentrate:

• High grade (High Cr₂O₃ content)

• Uniform particle size

• High density

• Heat and corrosion resistance

• Chemical stability

• Low impurity content

Applications of Chromite Concentrate:

• Production of ferrochrome (FeCr), a key ingredient in stainless steel manufacturing

• Used as heat-resistant mold sand

• Production of chromium compounds such as dichromate and industrial pigments

• Manufacture of chromite refractory bricks for furnaces and metal melting pots

• Used as pigment or additive in specialized formulations

• Production of heat- and corrosion-resistant alloys (especially in aerospace or high-performance engine parts)