Products Partgowal

Ferroalloys and Melting Raw Materials

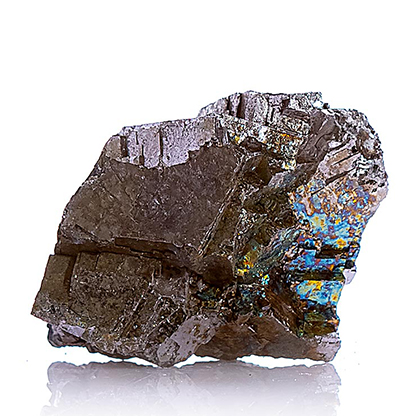

High Carbon Ferrochrome

HCFeCr

Ferrochrome, with the chemical symbol of FeCr, is one of the essential alloys in the steelmaking industry. It is produced through the carbothermic reduction of chromite ore in electric arc furnaces and plays a vital role in enhancing the mechanical properties of steel.

Types of Ferrochrome and their applications:

• High Carbon Ferrochrome

• Medium Carbon Ferrochrome

• Low Carbon Ferrochrome

What is High Carbon Ferrochrome?

High Carbon Ferrochrome (containing 6–10% carbon) is one of the most widely used types of this alloy. It is primarily produced in countries with abundant chromite ore resources.

Characteristics of High Carbon Ferrochrome:

High Carbon Ferrochrome is a combination of iron and chromium. Due to its high carbon content, it offers remarkable features such as:

• Enhanced mechanical strength of steel

• Improved wear resistance

• Increased final product hardness

• It is suitable for heavy-duty and demanding industrial applications. This alloy is used in the production of stainless steel, tool steels, and specialty cast irons.

Applications of High Carbon Ferrochrome:

• Production of stainless steel

• Manufacturing of tool steel and high-alloy steels

• Improving corrosion and wear resistance in steels

• Heat- and pressure-resistant cast irons

• Applications in automotive, oil and gas, and heavy industrial equipment industries

Low Carbon Ferrochrome

LCFeCr

Ferrochrome, with the chemical symbol of FeCr, is one of the essential alloys in the steelmaking industry. It is produced through the carbothermic reduction of chromite ore in electric arc furnaces and plays a vital role in enhancing the mechanical properties of steel.

• Types of Ferrochrome and their applications:

• High Carbon Ferrochrome

• Medium Carbon Ferrochrome

• Low Carbon Ferrochrome

• What is Low Carbon Ferrochrome (LCFeCr)?

Low Carbon Ferrochrome is one of the most important types of chromium-containing ferroalloys, characterized by its low carbon content (typically less than 0.1%). It plays a critical role in the production of high-precision and specialty steels that require strict chemical composition control.

• Key Characteristics of Low Carbon Ferrochrome:

• Very Low Carbon Content (<0.1%): Ideal for manufacturing high-purity steels

• High Chromium Content (60% to 70%): Enhances hardness and strength in steels

• Suitable for Carbon-Sensitive Steels: Such as stainless and tool steels

• High Thermal Stability: Maintains properties at elevated temperatures

• Low Levels of Impurities: Minimal phosphorus, sulfur, and silicon content

• Used in Precision Alloys where tightly controlled chemistry is required

• Applications of Low Carbon Ferrochrome:

• Production of stainless steel

• Manufacturing precision tool steels and high-strength alloy steels

• Oil, gas, and petrochemical industries

• Fabrication of corrosion- and heat-resistant components

• Automotive, aerospace, and medical equipment industries

• Production of welding electrodes and specialty engineering steels

High Carbon Ferro Manganese

FeMn

Ferro Manganese is a ferroalloy composed of iron (Fe) and manganese (Mn), widely used as an additive in steel production. It enhances the hardness, strength, and wear resistance of steel and serves as a powerful deoxidizer and desulfurizer.

Types:

• High Carbon Ferro Manganese

• Medium Carbon Ferro Manganese

• Low Carbon Ferro Manganese

High Carbon Ferro Manganese

Carbon content: 6%–8%

Features:

• Cost-effective manganese source

• Strong deoxidizing and desulfurizing agent

• Increases steel hardness and tensile strength

Applications:

• Carbon and low-alloy steel production

• Structural steels and castings

• Used in EAFs and converters

Medium Carbon Ferro Manganese

FeMn

Ferro Manganese is a ferroalloy composed of iron (Fe) and manganese (Mn), widely used as an additive in steel production. It enhances the hardness, strength, and wear resistance of steel and serves as a powerful deoxidizer and desulfurizer.

Type

• High Carbon Ferro Manganese

• Medium Carbon Ferro Manganese

• Low Carbon Ferro Manganese

Medium Carbon Ferro Manganese

Carbon content: 1%–2%

Features:

• Suitable for steels requiring high Mn with controlled carbon

• Better abrasion resistance than high carbon type

• Offers precise steel composition control

Applications:

• Engineering and precision tool steels

• Automotive and mechanical parts

• Corrosion- and pressure-resistant steels

Low Carbon Ferro Manganese

FeMn

Ferro Manganese is a ferroalloy composed of iron (Fe) and manganese (Mn), widely used as an additive in steel production. It enhances the hardness, strength, and wear resistance of steel and serves as a powerful deoxidizer and desulfurizer.

Types:

• High Carbon Ferro Manganese

• Medium Carbon Ferro Manganese

• Low Carbon Ferro Manganese

Carbon content: < 0.7%

Features:

• Ideal for high-grade alloy and stainless steels

• Minimal impact on carbon content

• Improves mechanical and corrosion resistance

Applications:

• Stainless and low-carbon steels

• High-spec applications in oil, gas, and petrochemical industries

• Steels requiring strict chemical composition

Ferro Molybdenum

FeMo

Ferro Molybdenum is a ferroalloy of iron (Fe) and molybdenum (Mo), used to enhance steel properties such as heat resistance, tensile strength, hardness, and corrosion resistance.

Features:

• Enhances high-temperature strength

• Improves corrosion and creep resistance

• Aids in welding, machining, and microstructure control

Applications:

• Stainless and tool steels

• Oil, gas, and petrochemical industries

• Aerospace and energy sectors

• Turbines, valves, and heat-resistant components

Ferro Vanadium

FeV

Ferro Vanadium is a ferroalloy of iron (Fe) and vanadium (V), added to steel for improved mechanical properties including strength, hardness, and fatigue resistance.

Features:

• Increases steel toughness and tensile strength

• Enhances wear and impact resistance

• Refines steel grain structure

Applications:

• Tool, structural, and alloy steels

• Automotive parts: crankshafts, springs, axles

• High-stress components in energy and rail industries

• Corrosion- and heat-resistant steels

Ferro Titanium

FeTi

Ferro Titanium is a ferroalloy of iron (Fe) and titanium (Ti), used as a powerful deoxidizer and denitrifier in steelmaking, enhancing grain structure and mechanical properties.

Features:

• Effective oxygen and nitrogen removal

• Improves corrosion resistance and strength

• Promotes fine grain structure

• Reduces impurities in molten steel

Applications:

• Stainless and high-strength alloy steels

• Deoxidation in steel melting furnaces

• Automotive and petrochemical components

• Heat- and corrosion-resistant steels

Ferro Silicon

FeSi

Ferro Silicon is a ferroalloy of iron (Fe) and silicon (Si), extensively used in steelmaking and casting as a deoxidizer and alloying agent.

Features:

• Strong deoxidizing effect

• Improves hardness and wear resistance

• Enhances corrosion and oxidation resistance

• Reduces shrinkage in casting

Applications:

• Carbon and alloy steel deoxidation

• Gray and ductile cast iron production

• Production of heat-resistant steels

• Used in magnesium and other metal reduction processes

Ferro Silicon Manganese

FeSiMn

Ferro Silicon Manganese is a ferroalloy composed of iron (Fe), silicon (Si), and manganese (Mn), used as an alloying element and deoxidizer in steelmaking.

Features:

• Strong deoxidizing and desulfurizing effects

• Enhances impact resistance and tensile strength

• Refenes grain structure and prevents cracking

Applications:

• Structural, carbon, and low-alloy steels

• Automotive, bridge, and tank construction

• Heavy-duty engineering components

• Wear-resistant ductile cast iron

Nickel

Ni

Nickel is a hard, ductile, and corrosion-resistant metal widely used in stainless steel production, high-performance alloys, and batteries.

Features:

• Excellent corrosion and oxidation resistance

• High electrical and thermal conductivity

• Silver-white appearance with high ductility

• High melting point (1455°C)

Applications:

• Stainless steel and heat-resistant alloys

• Lithium-ion and Ni-Cd batteries

• Electroplating (nickel coating)

• Aerospace and automotive industries

Copper Cathode

Cu

Copper cathodes are high-purity copper plates (up to 99.99%) produced via electrolytic refining, serving as a primary raw material in various industries.

Features:

• Very high purity

• Excellent electrical and thermal conductivity

• Fully recyclable

• High corrosion resistance and ductility

Applications:

• Wire and cable industry

• Electronics and printed circuit boards (PCBs)

• Fluid transport tubing

• Decorative and construction use

• Automotive and battery manufacturing