Products Partgowal

Producer, supplier and trader

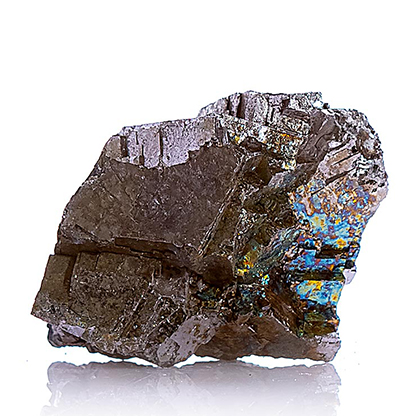

High Carbon Ferrochrome

HCFeCr

Ferrochrome, with the chemical symbol of FeCr, is one of the essential alloys in the steelmaking industry. It is produced through the carbothermic reduction of chromite ore in electric arc furnaces and plays a vital role in enhancing the mechanical properties of steel.

Types of Ferrochrome and their applications:

• High Carbon Ferrochrome

• Medium Carbon Ferrochrome

• Low Carbon Ferrochrome

What is High Carbon Ferrochrome?

High Carbon Ferrochrome (containing 6–10% carbon) is one of the most widely used types of this alloy. It is primarily produced in countries with abundant chromite ore resources.

Characteristics of High Carbon Ferrochrome:

High Carbon Ferrochrome is a combination of iron and chromium. Due to its high carbon content, it offers remarkable features such as:

• Enhanced mechanical strength of steel

• Improved wear resistance

• Increased final product hardness

• It is suitable for heavy-duty and demanding industrial applications. This alloy is used in the production of stainless steel, tool steels, and specialty cast irons.

Applications of High Carbon Ferrochrome:

• Production of stainless steel

• Manufacturing of tool steel and high-alloy steels

• Improving corrosion and wear resistance in steels

• Heat- and pressure-resistant cast irons

• Applications in automotive, oil and gas, and heavy industrial equipment industries

Low Carbon Ferrochrome

LCFeCr

Ferrochrome, with the chemical symbol of FeCr, is one of the essential alloys in the steelmaking industry. It is produced through the carbothermic reduction of chromite ore in electric arc furnaces and plays a vital role in enhancing the mechanical properties of steel.

• Types of Ferrochrome and their applications:

• High Carbon Ferrochrome

• Medium Carbon Ferrochrome

• Low Carbon Ferrochrome

• What is Low Carbon Ferrochrome (LCFeCr)?

Low Carbon Ferrochrome is one of the most important types of chromium-containing ferroalloys, characterized by its low carbon content (typically less than 0.1%). It plays a critical role in the production of high-precision and specialty steels that require strict chemical composition control.

• Key Characteristics of Low Carbon Ferrochrome:

• Very Low Carbon Content (<0.1%): Ideal for manufacturing high-purity steels

• High Chromium Content (60% to 70%): Enhances hardness and strength in steels

• Suitable for Carbon-Sensitive Steels: Such as stainless and tool steels

• High Thermal Stability: Maintains properties at elevated temperatures

• Low Levels of Impurities: Minimal phosphorus, sulfur, and silicon content

• Used in Precision Alloys where tightly controlled chemistry is required

• Applications of Low Carbon Ferrochrome:

• Production of stainless steel

• Manufacturing precision tool steels and high-strength alloy steels

• Oil, gas, and petrochemical industries

• Fabrication of corrosion- and heat-resistant components

• Automotive, aerospace, and medical equipment industries

• Production of welding electrodes and specialty engineering steels

High Carbon Ferro Manganese

FeMn

Ferro Manganese is a ferroalloy composed of iron (Fe) and manganese (Mn), widely used as an additive in steel production. It enhances the hardness, strength, and wear resistance of steel and serves as a powerful deoxidizer and desulfurizer.

Types:

• High Carbon Ferro Manganese

• Medium Carbon Ferro Manganese

• Low Carbon Ferro Manganese

High Carbon Ferro Manganese

Carbon content: 6%–8%

Features:

• Cost-effective manganese source

• Strong deoxidizing and desulfurizing agent

• Increases steel hardness and tensile strength

Applications:

• Carbon and low-alloy steel production

• Structural steels and castings

• Used in EAFs and converters

Medium Carbon Ferro Manganese

FeMn

Ferro Manganese is a ferroalloy composed of iron (Fe) and manganese (Mn), widely used as an additive in steel production. It enhances the hardness, strength, and wear resistance of steel and serves as a powerful deoxidizer and desulfurizer.

Type

• High Carbon Ferro Manganese

• Medium Carbon Ferro Manganese

• Low Carbon Ferro Manganese

Medium Carbon Ferro Manganese

Carbon content: 1%–2%

Features:

• Suitable for steels requiring high Mn with controlled carbon

• Better abrasion resistance than high carbon type

• Offers precise steel composition control

Applications:

• Engineering and precision tool steels

• Automotive and mechanical parts

• Corrosion- and pressure-resistant steels

Low Carbon Ferro Manganese

FeMn

Ferro Manganese is a ferroalloy composed of iron (Fe) and manganese (Mn), widely used as an additive in steel production. It enhances the hardness, strength, and wear resistance of steel and serves as a powerful deoxidizer and desulfurizer.

Types:

• High Carbon Ferro Manganese

• Medium Carbon Ferro Manganese

• Low Carbon Ferro Manganese

Carbon content: < 0.7%

Features:

• Ideal for high-grade alloy and stainless steels

• Minimal impact on carbon content

• Improves mechanical and corrosion resistance

Applications:

• Stainless and low-carbon steels

• High-spec applications in oil, gas, and petrochemical industries

• Steels requiring strict chemical composition

Ferro Molybdenum

FeMo

Ferro Molybdenum is a ferroalloy of iron (Fe) and molybdenum (Mo), used to enhance steel properties such as heat resistance, tensile strength, hardness, and corrosion resistance.

Features:

• Enhances high-temperature strength

• Improves corrosion and creep resistance

• Aids in welding, machining, and microstructure control

Applications:

• Stainless and tool steels

• Oil, gas, and petrochemical industries

• Aerospace and energy sectors

• Turbines, valves, and heat-resistant components

Ferro Vanadium

FeV

Ferro Vanadium is a ferroalloy of iron (Fe) and vanadium (V), added to steel for improved mechanical properties including strength, hardness, and fatigue resistance.

Features:

• Increases steel toughness and tensile strength

• Enhances wear and impact resistance

• Refines steel grain structure

Applications:

• Tool, structural, and alloy steels

• Automotive parts: crankshafts, springs, axles

• High-stress components in energy and rail industries

• Corrosion- and heat-resistant steels

Ferro Titanium

FeTi

Ferro Titanium is a ferroalloy of iron (Fe) and titanium (Ti), used as a powerful deoxidizer and denitrifier in steelmaking, enhancing grain structure and mechanical properties.

Features:

• Effective oxygen and nitrogen removal

• Improves corrosion resistance and strength

• Promotes fine grain structure

• Reduces impurities in molten steel

Applications:

• Stainless and high-strength alloy steels

• Deoxidation in steel melting furnaces

• Automotive and petrochemical components

• Heat- and corrosion-resistant steels

Ferro Silicon

FeSi

Ferro Silicon is a ferroalloy of iron (Fe) and silicon (Si), extensively used in steelmaking and casting as a deoxidizer and alloying agent.

Features:

• Strong deoxidizing effect

• Improves hardness and wear resistance

• Enhances corrosion and oxidation resistance

• Reduces shrinkage in casting

Applications:

• Carbon and alloy steel deoxidation

• Gray and ductile cast iron production

• Production of heat-resistant steels

• Used in magnesium and other metal reduction processes

Ferro Silicon Manganese

FeSiMn

Ferro Silicon Manganese is a ferroalloy composed of iron (Fe), silicon (Si), and manganese (Mn), used as an alloying element and deoxidizer in steelmaking.

Features:

• Strong deoxidizing and desulfurizing effects

• Enhances impact resistance and tensile strength

• Refenes grain structure and prevents cracking

Applications:

• Structural, carbon, and low-alloy steels

• Automotive, bridge, and tank construction

• Heavy-duty engineering components

• Wear-resistant ductile cast iron

Nickel is a hard, ductile, and corrosion-resistant metal widely used in stainless steel production, high-performance alloys, and batteries.

Features:

• Excellent corrosion and oxidation resistance

• High electrical and thermal conductivity

• Silver-white appearance with high ductility

• High melting point (1455°C)

Applications:

• Stainless steel and heat-resistant alloys

• Lithium-ion and Ni-Cd batteries

• Electroplating (nickel coating)

• Aerospace and automotive industries

Copper Cathode

Cu

Copper cathodes are high-purity copper plates (up to 99.99%) produced via electrolytic refining, serving as a primary raw material in various industries.

Features:

• Very high purity

• Excellent electrical and thermal conductivity

• Fully recyclable

• High corrosion resistance and ductility

Applications:

• Wire and cable industry

• Electronics and printed circuit boards (PCBs)

• Fluid transport tubing

• Decorative and construction use

• Automotive and battery manufacturing

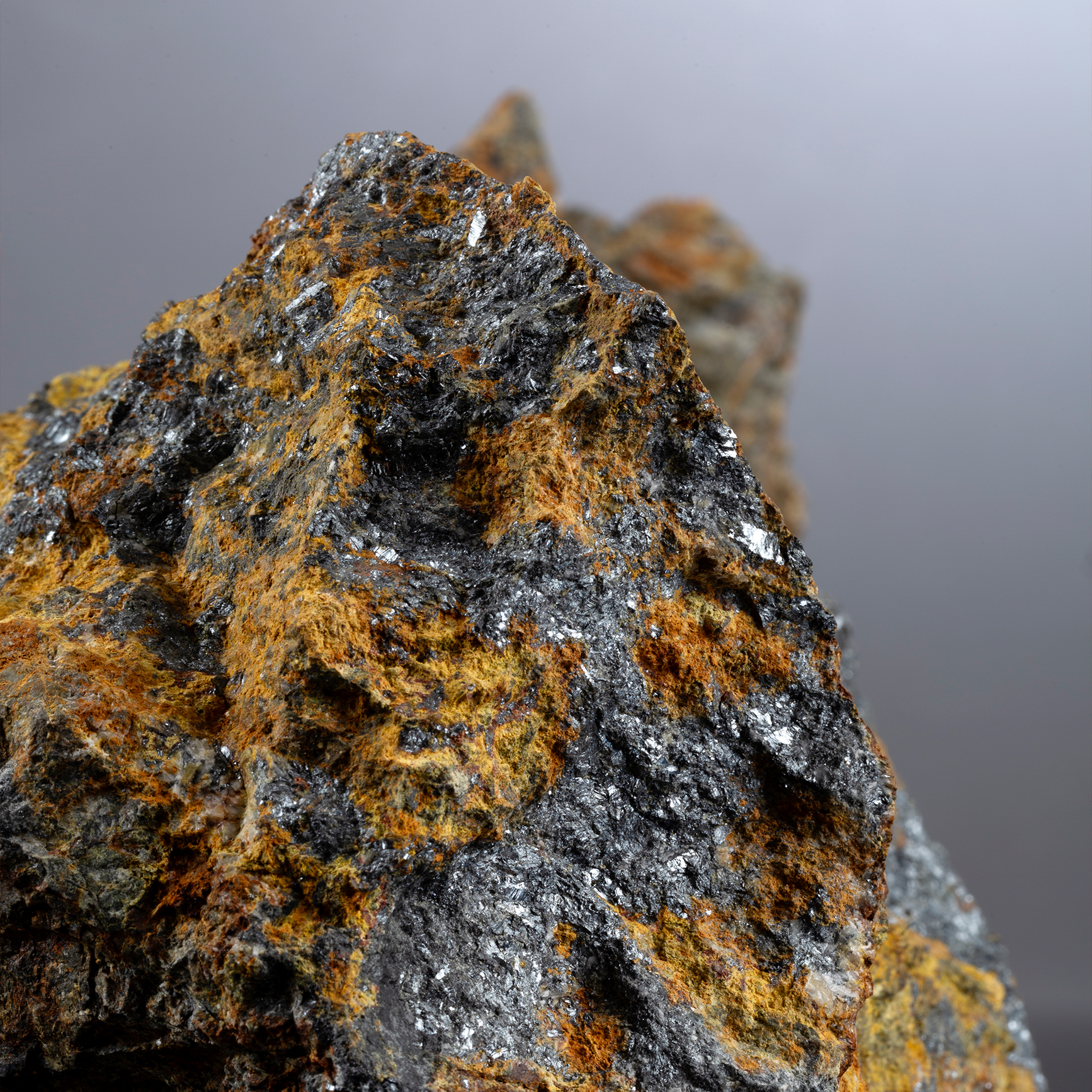

Chromite Ore

FeCr₂O₄

Chromite ore is the primary source of the metal chromium. It is a dark gray to black oxide mineral found in igneous and sedimentary rocks. Chromium is extracted from this ore and plays a vital role in the steel and alloy industries.

Characteristics of Chromite Ore:

• Relatively high hardness (5.5 to 6 on Mohs scale)

• High specific gravity (4.5 to 4.8 g/cm³)

• High thermal resistance

• Dark color with metallic to sub-metallic luster

• Chemical stability against oxidation

Applications of Chromite Ore:

• Production of ferrochrome (raw material for stainless and special steels)

• Manufacturing of heat- and corrosion-resistant alloys

• Production of refractory materials for furnace linings

• Preparation of industrial chemicals (e.g., chromium dioxide for pigments)

• Used in foundry industry as chromite sand

Copper Ore

CuO -Cu₂S-CuFeS₂

Copper ore is a mineral-rich rock that contains extractable quantities of copper metal. It is typically found in igneous, sedimentary, and metamorphic rocks and serves as the main source of copper supply for various industries.

Characteristics of Copper Ore:

• Distinct colors (green, blue, reddish-brown)

• High electrical and thermal conductivity

• Relatively high density

• Prone to oxidation when exposed to air

• High economic value due to metal content

Applications of Copper Ore:

• Extraction and production of pure copper for electrical and electronic industries

• Manufacturing of electrical wires and power transmission cables

• Production of alloys such as brass (copper & zinc) and bronze (copper & tin)

• Use in construction industry (pipes, fittings, roofing)

• Production of industrial parts, transportation equipment, and defense components

Antimony Ore

Sb₂S₃

Antimony ore contains the element antimony (Sb), typically found in the form of stibnite (Sb₂S₃). This material is used for producing antimony metal and its chemical compounds.

Characteristics of Antimony Ore:

• High specific gravity

• Corrosion resistance

• Medium hardness

• Brittle at low temperatures but excellent hardening agent in alloys

Applications of Antimony Ore:

• Production of wear-resistant alloys

• Additive in battery manufacturing (lead-acid batteries)

• Manufacturing of flame retardants

• Use in paint and ceramic industries

• Chemical industry for various additives

Fluorite Ore

CaF₂

Fluorite ore, also known as fluorspar, is a mineral composed of calcium fluoride (CaF₂) and serves as the primary source of fluorine for industrial applications. Due to its specific physical and chemical properties, it is used in metallurgy, chemical production, and ceramics.

Characteristics of Fluorite Ore:

• Moderate hardness (about 4 on Mohs scale)

• Good transparency and glassy luster

• Resistance to acids and high temperatures

• High melting point (around 1360°C)

Applications of Fluorite Ore:

• Used as a flux in steelmaking and foundry industries

• Production of hydrofluoric acid

• Manufacturing of ceramics and glazes

• Optical industry (lens and prism production)

• Chemical and pharmaceutical industries

Copper Concentrate

CuS -CuFeS₂-Cu₂S

Copper concentrate is the product of processed copper ore obtained through crushing, flotation, and impurity separation. It contains a high percentage of copper (Cu) and is used as the raw material for producing refined copper in smelting and refining industries.

Characteristics of Copper Concentrate:

• High copper content (approximately 20% to 30%)

• Contains sulfur (S)

• May include trace elements such as gold (Au), silver (Ag), molybdenum (Mo), and iron (Fe)

• Grayish-green to brownish color

Applications of Copper Concentrate:

• Production of refined copper through smelting and refining

• Electrical and electronics industries (wires, cables, electronic circuits)

• Construction industry (pipes, fittings, cladding)

• Automotive industry (electrical and motor parts)

• Production of copper alloys (brass, bronze)

Antimony Concentrate

Sb₂S₃

Antimony concentrate is obtained from mining and processing antimony-bearing ores. It contains a high percentage of antimony (Sb) and is used as a raw material for the production of antimony ingots and chemical compounds across various industries.

Characteristics of Antimony Concentrate:

• High antimony content

• Typically, gray to dark silvery color

• Relatively high density

• Corrosion resistance

• Easily meltable at lower temperatures than many other metals

Applications of Antimony Concentrate:

• Production of antimony ingots

• Battery manufacturing industry (improving the lifespan of lead-acid batteries)

• Manufacturing of corrosion-resistant alloys

• Chemical industry (production of antimony trioxide as a flame retardant)

• Electronics industry (used in semiconductors)

• Paint and plastic industries (as flame-retardant additives)

Chromite Concentrate

FeCr₂O₄

Chromite concentrate is a processed product derived from chromite ore (FeCr₂O₄). Through crushing and gravity or magnetic separation, the chromium content (Cr₂O₃) is upgraded, and impurities are reduced. It is produced as powder or granules and primarily used in metallurgy, especially for ferrochrome and stainless-steel production.

Characteristics of Chromite Concentrate:

• High grade (High Cr₂O₃ content)

• Uniform particle size

• High density

• Heat and corrosion resistance

• Chemical stability

• Low impurity content

Applications of Chromite Concentrate:

• Production of ferrochrome (FeCr), a key ingredient in stainless steel manufacturing

• Used as heat-resistant mold sand

• Production of chromium compounds such as dichromate and industrial pigments

• Manufacture of chromite refractory bricks for furnaces and metal melting pots

• Used as pigment or additive in specialized formulations

• Production of heat- and corrosion-resistant alloys (especially in aerospace or high-performance engine parts)

Steel and Iron Products

Fe₃O₃- Fe₂O₄

Iron concentrate is a processed product derived from iron ore by removing impurities such as silica, alumina, and sulfur. It contains a high percentage of iron (Fe) and serves as the primary raw material for pellet production and ultimately for crude iron in the steelmaking industry.

Characteristics of Iron Concentrate:

• High iron (Fe) content (typically above 66%)

• Low levels of impurities such as silica (SiO₂) and alumina (Al₂O₃)

• Gray to dark black color

• Defined particle size, compressible

• Suitable for pelletizing

Applications of Iron Concentrate:

• Production of iron pellets for use in blast furnaces or direct reduction

• Primary raw material for steelmaking

• Production of pig iron

• Use in foundry industries

• Export for global steel manufacturers

Cast Iron Ingot

Fe + C (2% to 4%) + Si, Mn, P, S

Cast iron ingot is a semi-finished metallic product obtained by remelting iron ore or scrap iron with carbon and other alloying elements. It serves as the raw material for manufacturing industrial cast iron components across various industries.

Characteristics of Cast Iron Ingot:

• High carbon content (between 2% and 4%)

• High hardness and wear resistance

• Excellent fluidity during casting

• Good resistance to wear and corrosion

• Relatively brittle (compared to steel)

Applications of Cast Iron Ingot:

• Manufacturing automotive parts (e.g., brake discs, engine cylinders)

• Production of industrial components (e.g., valves, pump housings)

• Kitchenware manufacturing (e.g., stoves, cast iron pots)

• Fabrication of heavy machinery parts and mining equipment

Rebar

Fe (Iron) + C, Mn, Si, S, P

Rebar, or reinforcing bar, is a steel rod with a plain or ribbed surface used to enhance the tensile strength of concrete structures. While concrete is strong in compression, it is weak in tension; rebar compensates for this deficiency.

Characteristics of Rebar:

• High tensile strength

• Good flexibility

• Excellent adhesion with concrete (especially in ribbed bars)

• Corrosion resistance (in galvanized or stainless types)

• Weldable and bendable in certain grades

Applications of Rebar:

• Construction of various concrete structures (buildings, bridges, dams, tunnels)

• Reinforcement of concrete floors and walls

• Manufacturing of precast concrete components

• Construction of earthquake-resistant steel frames

• Major infrastructure projects (e.g., metro, railways)

Billet

Fe (Iron) +C, Mn, Si, S, and P

A billet is a semi-finished steel product with a square cross-section and relatively small dimensions. It is primarily used for rolling into rebars, I-beams, wire rods, and other steel profiles.

Characteristics of Billet:

• Uniform structure and high metallurgical quality

• Good mechanical strength and toughness

• Suitable for hot and cold rolling processes

• Excellent weldability and machinability

• Resistance to cracking

Applications of Billet:

• Production of construction rebar

• Manufacturing of I-beams, angles, and channels

• Production of steel wires and cables

• Manufacturing components for machinery and steel structures

Agglomerate

Fe₂O₃

Agglomerate refers to porous masses made from fine mineral particles (primarily iron ore) that are bonded together through the agglomeration (sintering) process involving heat or pressure. The purpose of agglomerate production is to improve the quality of feedstock for blast furnaces in crude iron production.

Characteristics of Agglomerate:

• Increased porosity compared to raw iron ore

• More uniform particle size distribution

• Improved reducibility in blast furnaces

• Reduction of dust during melting processes

• Resistant to breakage during handling and transportation

Applications of Agglomerate:

• Main feedstock for blast furnaces in crude iron production

• Enhancing furnace efficiency

• Reducing coke consumption in blast furnaces

• Optimizing the quality and composition of exhaust gases in furnaces

High Sulfur Graphite

CPC

High sulfur graphite petroleum coke is a carbon-rich material produced through the calcination of petroleum coke, characterized by a relatively high sulfur content. Due to its high carbon value and lower cost compared to low-sulfur types, it is used in specific foundry applications and cast-iron production where sulfur sensitivity is lower.

Characteristics of High Sulfur Graphite Petroleum Coke:

• High carbon content (85% to 95%)

• Higher sulfur content compared to low-sulfur grades

• Cost-effective for applications less sensitive to sulfur

• Acceptable electrical conductivity

• Graphitic crystalline structure

Applications of High Sulfur Graphite Petroleum Coke:

• Carbon additive in melting processes of gray and ductile cast iron

• Utilized in heavy-duty foundries and cast-iron manufacturing plants

• Suitable for operations with lower sulfur purity requirements

• Used in the production of low-cost carbon electrodes

Low Sulfur Graphite

GPC

Low sulfur graphite petroleum coke is a graphitized coke with extremely low sulfur content. Due to its high carbon purity and minimal impurities, it is widely used in high-grade and sensitive applications such as advanced steelmaking and high-quality ductile iron production.

Characteristics of Low Sulfur Graphite Petroleum Coke:

• Very high carbon content (98% to 99%)

• Extremely low sulfur (less than 0.05%)

• Low ash content

• Excellent electrical conductivity

• Fully developed graphitic crystalline structure

• High thermal and chemical resistance

Applications of Low Sulfur Graphite Petroleum Coke:

• Production of special steels and sensitive alloys

• Carbon addition in precision foundries and high-quality ductile iron manufacturing

• Used in the production of advanced graphite anodes

• Applied in industries requiring high carbon purity and minimal impurities

• Battery manufacturing, precision metallurgy, and refractory industries

Coke is a carbon-rich material produced by heating high-grade coal in the absence of air (a process known as coking). It is primarily used in metallurgical industries, particularly in the production of steel and cast iron, serving as both a fuel and a reducing agent.

Types of Coke by Application:

• Metallurgical Coke:

Mainly used in blast furnaces for steel production.

• Petroleum Coke (Pet coke):

A by-product of crude oil refining, used in aluminum production, electrode manufacturing, and as an energy source.

• Chemical Coke:

Utilized in the production of chemical compounds.

• Foundry Coke:

Designed for cast iron foundries, featuring larger size and high resistance to breakage.

• Breeze Coke:

Very fine particles, used as fuel in small-scale industries or in thermal processes.

Coke Size Classification:

• 80–150 mm: For cast iron foundries

• 25–80 mm: Primary size for blast furnace use

• 10–25 mm: For use in smaller furnaces

• Less than 10 mm: Used as fuel or in specialized processes

Characteristics of Coke:

• High carbon content (85% to 95%)

• Very high calorific value

• Good mechanical strength (resistance to crushing)

• Low volatile matter

• Adequate thermal conductivity

• High resistance to thermal shock and elevated temperatures

Applications of Coke:

• Primary fuel in blast furnaces for pig iron production

• Reducing agent in metallurgical processes for metal extraction from ores

• Used in ferroalloy industries for the production of materials like ferromanganese and ferrochrome

• As a raw material in the synthesis of certain industrial chemicals

• In aluminum smelting (calcined petroleum coke)